Bring Your Best Ideas to Life with Precision Prototyping

You’ve done the hard part—the thinking. We handle the making.

Prototyping is the most critical bridge between a concept and a finished product.

At 3DGateway, we provide a comprehensive prototyping service that helps you validate designs, test functionality, and refine your vision.

We don’t just hit “start” on a machine. We look at your project through the lens of an engineer and an inventor. We leverage a diverse suite of manufacturing technologies to ensure your prototype isn’t just a “model,” but a high-fidelity representation of your final product.

We believe your invention deserves a direct connection to the people making it. Because we fabricate everything right here in our shop, we don’t have to pass along the high costs of outsourcing or third-party management fees. You save on costs, avoid communication gaps, and stay updated through every step of the build.

| Other Brokerage | 3DGateway |

|---|---|

| Middleman Markups: Platform fees inflate your project costs. | Transparent Pricing: Direct-from-shop rates mean better pricing—period. |

| Communication Lag: Inquiries filter through sales teams and account managers. | Direct Line to the Machinist: Speak immediately with the expert running your job for fast, technical feedback. |

| Delayed Iteration: Changes require multiple communication loops. | Rapid Design Feedback: Accelerate your design-build-test cycle with on-the-spot technical consultation. |

Ready to Launch Your Project?

Experience the difference that direct partnership makes. Get started now and secure better pricing and superior technical support. Get Your Instant Quote Now!

QUOTE YOUR CUSTOM CNC PART NOW

3MF | 3DXML | STEP | STP | SLDPRT | STL | SAT | DXF | IPT | PRT | PNG | JPEG

3MF | 3DXML | STEP | STP | SLDPRT | STL | SAT | DXF | IPT | PRT | PNG | JPEG

All uploads are confidential.

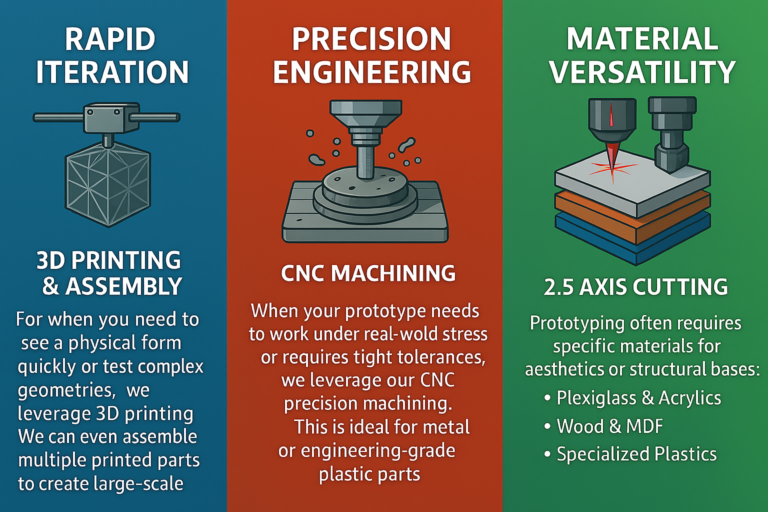

How We Leverage Our Technology for Your Prototype

Every project has different requirements for strength, clarity, and precision. We choose the right tool for the job:

-

For Rapid Iteration: 3D Printing & Assembly When you need to see a physical form quickly or test complex geometries that traditional machining can’t reach, we leverage 3D printing. We can even assemble multiple printed parts to create large-scale functional prototypes.

-

Precision Engineering: CNC Machining When your prototype needs to work under real-world stress or requires tight tolerances, we leverage our CNC precision machining. This is ideal for metal or engineering-grade plastic parts that need to perform exactly like the final production piece.

-

For Material Versatility: Precision Sheet Cutting (2.5 Axis) Prototyping often requires specific materials for aesthetics or structural bases. We offer precision cutting for:

-

Plexiglass & Acrylics (For enclosures or “see-through” functional tests)

-

Wood & MDF (For structural frameworks and architectural models)

-

Specialized Plastics (For durable, cost-effective components)

-

3D Printing Prototyping & Assembly

Prototyping Materials

We offer professional-grade prototyping using a versatile range of high-performance filaments. Our advanced multicolor printing capabilities allow you to integrate intricate, multi-tonal details directly into your build, ensuring your prototypes are as visually striking as they are functional.

Visual & Concept Prototyping

Best Filaments: PLA, Matte PLA, Multicolor

Needs: Rapid iteration, high-detail visualization, and aesthetic accuracy.

Best For: Marketing samples, architectural models, and early-stage design “mockups” where fit and form are more important than mechanical strength.

Multicolor Edge: Perfect for integrating branding directly into the part or highlighting specific functional areas without painting.

Functional & Durable Testing

Best Filaments: PETG, ABS

Needs: Impact resistance, moderate heat tolerance, and structural integrity.

Best For: Snap-fit assemblies, protective housings, and mechanical brackets that need to withstand daily use.

Relationship Focus: Ideal for creating shared tools for your “tribe” that need to survive more than just a shelf display.

Outdoor & Environmental Survival

Best Filaments: ASA

Needs: High UV resistance, weatherproofing, and heat stability.

Best For: Shelter components, garden equipment, and automotive accessories. Unlike other plastics, ASA won’t become brittle or yellow when left in the sun, making it the gold standard for parts living in the elements.

High-Performance Engineering

Best Filaments: Carbon Fiber (PLA-CF, PETG-CF, PA-CF)

Needs: Extreme stiffness, lightweight strength, and dimensional stability.

Best For: High-stress structural parts like drone frames, specialized tool handles, or any prototype where “flex” is the enemy.

Surface Finish: Offers a professional, matte-black industrial look that masks layer lines beautifully.

Ergonomic & Flexible Solutions

Best Filaments: TPU

Needs: Shock absorption, flexibility, and chemical resistance.

Best For: Ergonomic grips, gaskets, seals, and protective “bumpers” for safety equipment. TPU allows you to prototype parts that need to stretch or compress under pressure.

Safety & Instructional Design

Best Filaments: Multicolor (Any Material)

Needs: Clear communication, color-coded safety warnings, and intuitive assembly.

Best For: Creating safety tools with “High-Viz” sections or complex assemblies where different colors represent different functional groups (e.g., “Press here” in red).

CNC Capabilities & Materials:

We specialize in precision subtractive manufacturing, accommodating a vast range of complexity and material requirements, including:

6061: Excellent strength-to-weight ratio, superb machinability, and good weldability. Ideal for general-purpose structural components, machine parts, and enclosures where cost-effectiveness and performance are key.

7075: Higher strength aluminum (comparable to many steels), offering superior fatigue resistance. Preferred for aerospace components, high-stress parts, and applications demanding maximum strength.

303: The most machinable stainless steel, excellent for parts requiring extensive turning or milling. Offers good corrosion resistance.

304: Good all-around corrosion resistance, strength, and weldability. Common for food and beverage equipment, medical instruments, and general industrial use.

316: Superior corrosion resistance, especially against chlorides and acids. Essential for marine, chemical processing, and medical implant applications.

Known for its outstanding machinability, good electrical conductivity, and attractive appearance. Often used for fittings, connectors, decorative parts, and components requiring low friction.

Grade 2 (Commercially Pure): Good strength, ductility, and excellent corrosion resistance. Suitable for chemical processing and marine environments.

Grade 5 (Ti-6Al-4V): The most common and versatile titanium alloy, offering an exceptional strength-to-weight ratio, high fatigue strength, and biocompatibility. Critical for aerospace, medical implants, and high-stress components.

A widely used, cost-effective engineering thermoplastic. Offers good impact strength, toughness, and ease of machining. Ideal for functional prototypes, consumer products, and enclosures.

High strength, exceptional impact resistance, and optical clarity. Great for robust housings, protective covers, light pipes, and components requiring transparency and durability.

Excellent wear resistance, toughness, and chemical resistance. Common for gears, bearings, bushings, and structural components in various industries. Glass-filled variants offer enhanced stiffness and strength.

Known for its low friction, high stiffness, and excellent dimensional stability. A top choice for precision gears, bearings, snap-fit components, and moving parts that require high wear resistance.

A high-performance polymer. Offers exceptional strength, stiffness, and thermal/chemical resistance in extreme environments. Essential for aerospace, medical (autoclavable), and high-temperature industrial applications.

Precision Sheet Cutting (2.5 Axis)

Subtractive Sheet Fabrication

While 3D printing builds objects layer-by-layer, Precision Sheet Cutting (often called 2.5 Axis machining) carves parts out of solid, flat sheets of material. This process is the bridge between a digital sketch and a structural reality, allowing for the rapid creation of high-strength panels, mounting plates, and complex flat profiles that 3D printers cannot match in sheer durability.

Plexiglass & Acrylics (Transparency & Protection)

Use Case: Custom-fit safety guards, “see-through” functional enclosures for internal testing, and sleek branding displays.

The Benefit: Offers high-clarity visibility for inspecting moving parts or protecting your tribe from debris without blocking their view.

Wood & MDF (Structural Foundations)

Use Case: Rigid frameworks for architectural models, heavy-duty baseplates for machinery, and ergonomic furniture mockups.

The Benefit: A cost-effective, sturdy solution for creating the “bones” of a prototype or building rapid shelters and mounts.

Specialized Plastics (Industrial Durability)

Use Case: High-impact spacers, chemical-resistant trays, and sliding components like bushings or rails.

The Benefit: Uses engineering plastics like Delrin or HDPE that provide low friction and extreme durability for parts that will see heavy use in the field.

Composite Panels (Advanced Strength)

Use Case: Lightweight mounting panels for electronics and weather-resistant outdoor signage.

The Benefit: Perfect for when you need a prototype that is incredibly light but won’t flex or warp under environmental stress.

TALK TO US

We partner with businesses and individuals to deliver a range of services, including:

Prototyping

3D Modeling for Product Design

3D Printing for Functional Prototypes

CNC Machining for Engineering & Parts

Powder Coating | Durable & Protective Finishes for Metal Parts